You have no items in your shopping cart.

0

You have no items in your shopping cart.

This method is intended for determining the resistance to abrasion of slackline webbing.

The specimen shall be the full width of the material being tested and shall have a minimum length of 54 inches (1,372 mm).

Unless otherwise specified in the procurement document, five (5) specimens shall be tested from each sample unit.

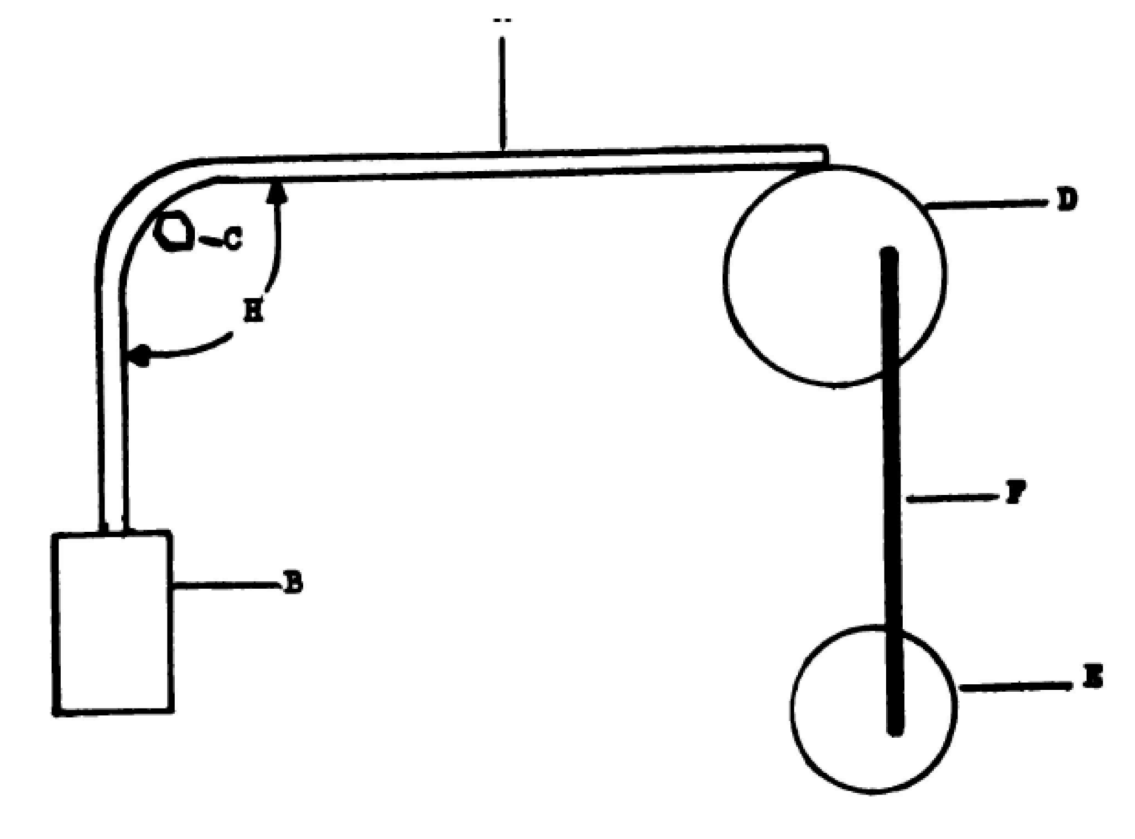

Webbing Abrasion Tester. The webbing abrasion tester (principle illustrated in Figure 1) consists of a power driven oscillating drum. One end of each specimen is attached to the drum and the other end passing over a hexagonal steel rod is attached to a weight. The hexagonal rod is so fixed as to subject the webbing specimen to abrasion on two adjacent edges as the drum moves the specimen across the rod.

Weight “B”, unless otherwise specified in the procurement document, shall be 2 pounds ± 2 ounces (0.91 kg + 0.06 kg) for specified breaking strengths up to 1000 pounds ± 4450 N), 4 pounds ± 2 ounces (1.81 ± 0.06 kg) for breaking strengths of 1000 to 3000 pounds (4450 to 13350 N), and 5.2 pounds ± 2 ounces (2.4 +0.06 kg) for breaking strengths over 3000 pounds (13350 N).

Steel hexagonal rods “C” shall be 0.250 ± 0.001 inch (6.35 ± 0.03 mm) when measured across opposite flat sides and the radius of the edges shall be 0.020 ± 0.004 inch (0.5 ± 0.1 mm). The steel shall have a cold drawn finish and a Rockwell Hardness of B-97 to B-101 (see 6.1). The edges of the hexagonal rods shall not have any burrs, nicks or scale.

Drum “D” shall have an outside diameter of 16 inches (406 mm) with a suitable means for attaching the specimen to be tested without damage to specimen.

The crank “E” and crank-arm “F” shall be attached to the drum in such a manner that when the specimen is attached to the drum, the specimen during the test will oscillate over the hexagonal rod the required distance during each stroke and at the required rate.

The hexagonal rod shall be so placed that specimen “A” with the weight attached to one end and the other end passing over the hexagonal rod and attached to the drum will form an angle of 85 ± 2 degrees “H”.

Unless otherwise specified in the procurement document, the specimens tested shall be conditioned and tested under standard conditions in accordance with Section 4 of this Standard.

Attach the required weight to one end of the specimen, pass the other end over the hexagonal rod and attach to the drum. The length of the specimen shall be adjusted, without altering the original length, so that the specimen shall oscillate across the hexagonal rod and that each end of the abraded area is equidistant from the ends of the specimen.

The edges of each new hexagonal rod shall be identified as 1 through 6, and only alternate edges (e.g., 1, 3, and 5) shall be used for abrading. No abrading edge shall be used more than once.

Oscillate the drum so that the specimen is given a 12 ± 1 inch (305 ± 25 mm) traverse over the rod at the rate of 60 ± 2 strokes (30 ± 1 cycles) per minute for 5000 strokes (2500 cycles). One single stroke is 12 ± 1 inches (305 ± 25 mm) in one direction only.

Calculation of results.

Percent change in the characteristic being evaluated to determine resistance to abrasion shall be calculated as follows:

Percent change in characteristic = (A - E) / Δ * 100

Where:

A = Breaking strength value before abrasion

E = Breaking strength value after abrasion

| Product | Price | Quantity | Options | |||||

|---|---|---|---|---|---|---|---|---|

| Features |

| Availability: |

| Price |

| Options |

| Actions |

← Older Post Newer Post →

0 comments