You have no items in your shopping cart.

0

You have no items in your shopping cart.

Today we are looking at the Alpine WebLock to see which version retains the most strength. We are only looking at the Alpine WebLock 4.0, 5.0, and 6.0 series as these are the most popular and most widely used models of our weblock.

Each of these 3 devices differs greatly in their geometry. Not only do they all have different sizes of Diverter, but the distance from the diverter to the pin is different, the pin location relative to the diverter in the vertical direction is different, the size of the pin is different, and the general construction of the device is different. It will be impossible for us to attribute any differences we see to one of these variables, so we will not dive into that with too much detail. Instead, we will focus on the pure results we get to see if there is a difference at all.

In order to look at strength retention values, we need a baseline strength for every slackline webbing we test (Control Group). In order to do this, we have opted to follow the guidelines of the ISA with how they test slackline webbing in order to be ISA certified. They use a device called the "Whale", which is a webbing anchor with an 80mm diverter and no webbing overlap on the first bend. We built our own version of this device, dubbed the "Blue Whale", and used it on every webbing we tested. Our version requires a sewn loop on each end of the webbing we test, which is anchored to a grade 9 bolt going through the Blue Whale.

The webbing wraps around the Blue Whale main diverter, around the center bolt, and then back up to the back bolt, where the sewn loop is anchored. Each side of the sample wraps around the main diverter in the opposite direction, giving an even loading through the thickness of the webbing.

Each sample starts as a 6.5 foot (roughly 2 meters) piece, then a 5.5 inch (14 cm) length is folded over on each end and a sewn loop is added. The final sample length is then 5 ft 7 inches (170 cm). We have learned throughout these tests that long samples are a necessity. We get drastically more variance with short samples.

Each webbing tested has at least 4 samples, and up to 8 samples done. The 4 sample types were done because we ran out of material.

After having a Control Group to test against, we ran our test samples. This includes three main groups: AWL4, AWL5, and AWL6.

Over 270 samples were tested in the sample groups. Each webbing tested has a minimum of 5 samples and up to 8 samples. The larger sample sizes were done on webbings we experienced a lot of variance on. Most of the time this was attributed to short sample lengths.

Each webbing starts as a 5 foot sample and we tried to maximize this length by installing in the weblocks at the very end of the sample. Early on in the testing process, we weren't as diligent in this process, which accounted for a lot of the variance we saw in the testing.

For 25mm/1-inch webbings, we used the weblocks as intended. For 20mm webbings, we used spacers for the weblocks. All samples were installed in the weblocks in the standard, approved way.

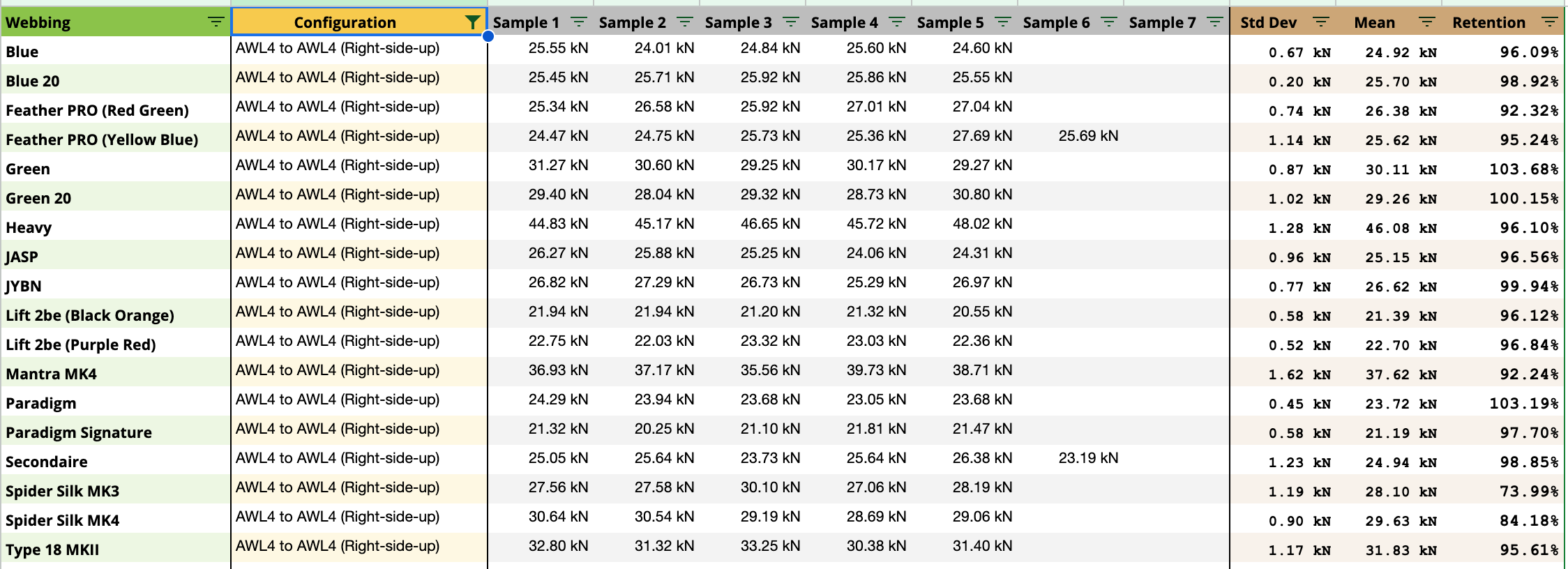

Here we have the average results for each sample group:

Another interesting comparison is material type. Do specific materials perform better in specific weblocks? Let's see:

The High Tech needs more data as we only had 2 different webbings to test. With our coming high tech webbings, we will be able to double that sample size, which will then be added to this test report.

Furthermore, another interesting comparison is width. Do 20mm webbings do better in a specific weblock? However 40% of our 20mm webbings are high tech, so that may be throwing the results off a bit:

Throughout the testing, one thing became very clear to be a major influence on the result: sample length. A lot of our early tests were done with long tails on the weblocks. For these webbings, we saw very large variance in the samples. If we were to do this study again, the tail lengths would be a standard for the experiment. I apologize about that inconsistency. For others that are interested in doing tests like this, we highly recommend maximizing your sample lengths as much as possible. Not only does that represent real-life usage more, it also allows room in the sample to equalize a lot better. Webbing flaws are exaggerated with short sample lengths.

Looking through the results from above, it's quite clear the AWL4 and AWL6 are a level above the AWL5. However, all three devices yield spectacular strength retention on most webbings (in excess of 90%). Some samples in the AWL4 and AWL6 groups (and one in the AWL5 group) yielded more than the Blue Whale, which I find very fascinating.

Speaking about the differences between these 3 devices, the AWL5 has the most deviation from the others. The diverter is the smallest (starting at 36mm and ending at 20mm), the front pin is the smallest in diameter (11.1mm), the front pin is the lowest with respect to the Diverter, and the front pin is the closest to the diverter. This combination has lead to it yielding the worst results of the 3.

The AWL6 has the largest diverter (38mm all the way around). It's clear that this makes a big difference in lower stretch materials like Polyester and High Tech, where it outshined the other 2 models by a pretty decent margin. It doesn't matter as much for nylon samples, where all the weblocks did pretty similarly on most webbings.

Weblocks, when used correctly, are very strong anchors for our slackline webbings. Even a design that is very obscure from a standard weblock design can average over 90% on most slackline webbings. However, to get that extra edge and average over 95% on most slackline webbings, a weblock must maximize every detail to edge just a few more kN out of the webbing sample. Most of the time, this added retention is not necessary. However, when dealing with high tensions or low strength webbings, every additional newton of strength you can get out of the webbing matters.

One last thing about this testing, we used the same 6 weblocks for the entire study. Each weblock was taken to over 20 kN, many times over 30 kN, at least 180 times. The AWL5 and AWL6, both being stronger than 80 kN and made from a single block of aluminum, did the best (we did end up going through about 6 front pins on the AWL5 though). These devices will continue to be used in our test machine. The AWL4's did quite a bit worse. The body is flaring out at the end, the anchor hole is splitting, and the hole for the front pin has elongated significantly. We don't have many more tests with these devices and may need to use a new set for future testing.

Thanks for reading through our tests results. If you have any questions or comments, please leave them below or get in contact with us.

| Product | Price | Quantity | Options | |||||

|---|---|---|---|---|---|---|---|---|

| Features |

| Availability: |

| Price |

| Options |

| Actions |

← Older Post Newer Post →

0 comments