You have no items in your shopping cart.

0

You have no items in your shopping cart.

We've already looked into the main pulleys for you pulley system, now on to the next component: the Brake! If you have ever tensioned a slackline before, you've probably noticed that the tension doesn't just 'stay' in the line. You need a way to hold this tension in place. This is usually achieved by using some sort of braking device set behind your main pulleys. By behind, I mean that the rope in your pulley system will travel through your main pulleys first and then go to your brake device where the tension will be held.As with the main pulleys, there are a few things that are important when looking into different braking devices:

I will explain each of these characteristics in detail below.

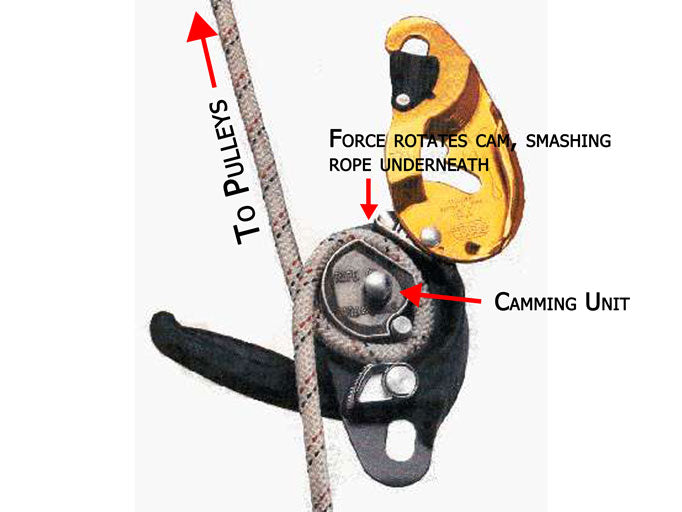

Different brakes have different methods of holding on to the rope. The most common method of braking a rope is known as the 'camming' method, which involves using the force that is on the rope to pivot a half-moon-shaped piece of metal such that it squishes the rope beneath it, thus preventing it from being able to move.

Using this method of braking, it is necessary for the rope to change directions. For this reason, the larger the camming piece, the less friction there will be within the device. The devices with smaller camming units will typically be much more difficult to release tension as well, because of the much higher friction within the device (plus, these devices will typically have smaller handles for releasing tension).

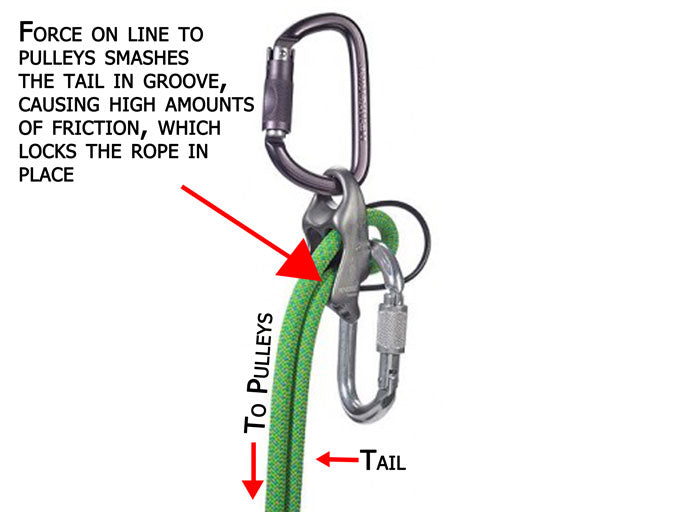

Another braking method that is quite common does not have an official name, but we will refer to them as "Smashing-Method Brakes". It's typically found on certain types of ATC's (belay devices) and involves taking the loaded end of the rope and using it to smash the rope tail such that it is not able to move.

This method involves a very large amount of friction and can rob a significant amount of your mechanical advantage. Another thing about these types of brakes is that they require the use of a smaller diameter of rope because the groove in which the rope is smashed is usually quite small and can destroy larger ropes. The benefit of these types of brakes is that they are quite cheap compared to the far superior camming-type brakes.

One of the most dangerous parts of rigging a slackline is releasing tension from the line. If you have a brake that has a lot of control when releasing tension, detensioning can become very easy and very safe. One of the easiest ways to tell if a brake will be easy to release tension from is the size of the handle on the device. Some devices have a VERY small handle, or no handle at all (read: Grigri and all smashing-method brakes), which makes releasing tension extremely difficult and quite dangerous. There have been many instances where I have seen people come very close to getting severly injured during detensioning using one of these devices.

Most devices that use the camming-method to brake will be significantly easier to detension than their smashing-method counterparts. This is because these devices typically come with a handle that can be controlled very well, even under extreme tensions. Although, the longer the handle the device has, the easier the release of tension will be. This is due to the amount of torque you have on releasing the camming device: the longer the handle, the more torque you have.

This topic is a hard one to cover since most devices that we use for braking our tensioning system are not meant for this application. They are typically belay devices that happen to work perfectly for our sport. Typically, how these types of devices are strength rated is by 'person load'. For instance, the Petzl GriGri 2 does not have any published breaking strength, but it is typically used as a single person belay device. This means that it's capable of holding a factor 2 fall in rock climbing, which can be upwards of 8 kN of force on the device. This type of loading is known as shock loading, and is completely different from a sustained load. I typically suggest that you limit the force on your GriGri 2 to about 600 lbf, which is roughly 3,000 lbf if using a 5:1 pulley system (whole other post).

Other brake devices publish their strength limitations as they are often used for rescue situations where sustained loads are more common. For instance, on Petzl's website (www.Petzl.com) they have a chart in which they show test results of pulling on ropes which were anchored with the Petzl RIG, and they were showing slipping loads as low as 4.8 kN (1,079 lbf). This is much higher than the proclaimed 2.7 kN that has been stated for the Petzl GriGri 2.

The best of the best braking devices, such as the CMC MPD, publish their actual breaking strengths and decent control loads. These are the most trusted devices for this application because they are built for holding and releasing tension. However, they cost over $600, which can be quite the turnoff for many. The Edelrid braking devices offered by Balance Community are a great compromise on quality and price. I have rigged several lines well in excess of 1,000 ft. using any of the devices offered by Balance Community.

This topic is especially important for pulley systems which are used for highlines. The heavier your brake device, the heavier your pack will be. Typically, a lighter device will be less than optimal in other categories, but sometimes the added weight savings is worth the lower strength rating, difficulty of detensioning, and unfavorable braking method. However, there are devices out there that have a moderate weight and excel in other categories, such as the Petzl RIG. An awesome device in a small package (more later).

Keep in mind that heavier brake devices are heavier for a reason: they have bigger components. For instance, the CMC MPD weighs in at 2 lbs 8 oz., and that's because it comes with a 3" steel sheave and has stainless steel sideplates. The Petzl RIG weighs in at 380 grams and has a camming unit that is roughly 1/3 the size of the CMC MPD's sheave. It's all about where you are using your brake though, if weight is not an issue, then heavier usually means stronger and less friction.

As with any gear related items (or anything, pretty much), you get what you pay for. Don't let the price fool you though! Sometimes a cheaper brake will better suit your needs compared to a much more expensive one. For instance, if you are planning on doing a highline with a massive approach, it would probably be a good idea to avoid the CMC MPD and stick with the Edelrid Eddy instead, as it's about 1/6 the weight. So just take into account all the above characteristics as well as the projects that you will be working on before deciding on a brake device.

| Product | Price | Quantity | Options | |||||

|---|---|---|---|---|---|---|---|---|

| Features |

| Availability: |

| Price |

| Options |

| Actions |

← Older Post Newer Post →

0 comments