You have no items in your shopping cart.

0

You have no items in your shopping cart.

There are a number of ways that slackliners use slings, which are typically spansets, that are non-standard. Until now, we just believed that because of how strong spansets are, that no matter how we rigged with them we could be sure that they would be strong enough. Well, I wanted to test a few different methods that are commonly used by slackliners to see just how strong the spansets actually are.

For all of these tests, a slow-pull destructive test was done using a hydraulic pull testing machine. Each test produced a graph with time on the X-axis and force on the Y-Axis. All tests were done using Green Spansets of various lengths, depending on the test.

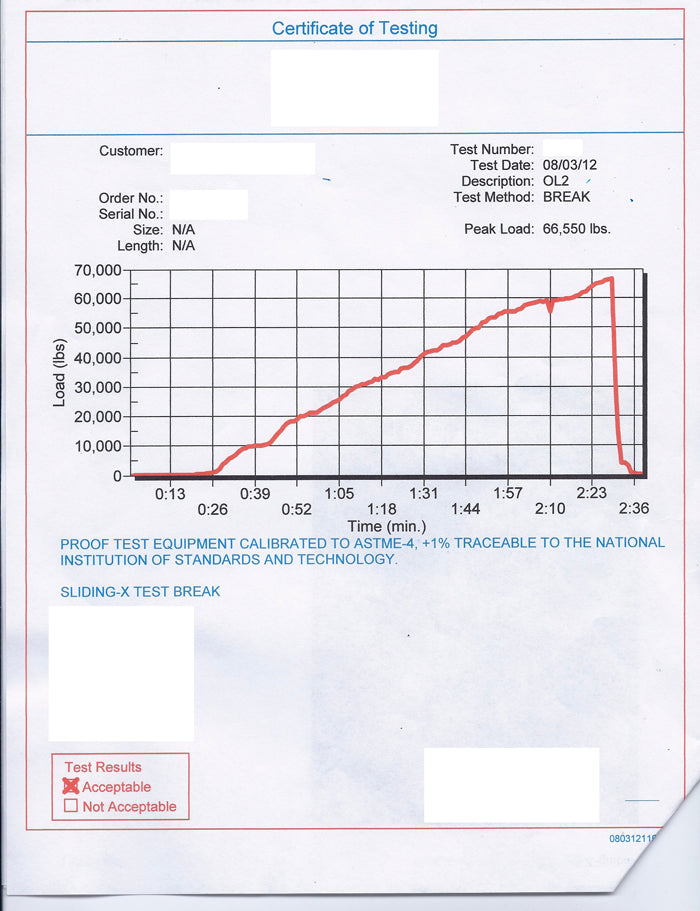

We used four connection points with the sliding-x. Each point was connected to the green spanset with a 1/2" Shackle. We initially used steel carabiners, but the carabiners broke before the spanset did (comforting). So we had to redo the tests with a stronger connector. The master point went to a large, 1" shackle that was connected directly to the hydraulic cylinder.

The force we achieved was 66,550 lbf (296 kN). Given that our spansets have a 5:1 safety ratio, the green spansets have a 13,310 lbf working load limit with this configuration.

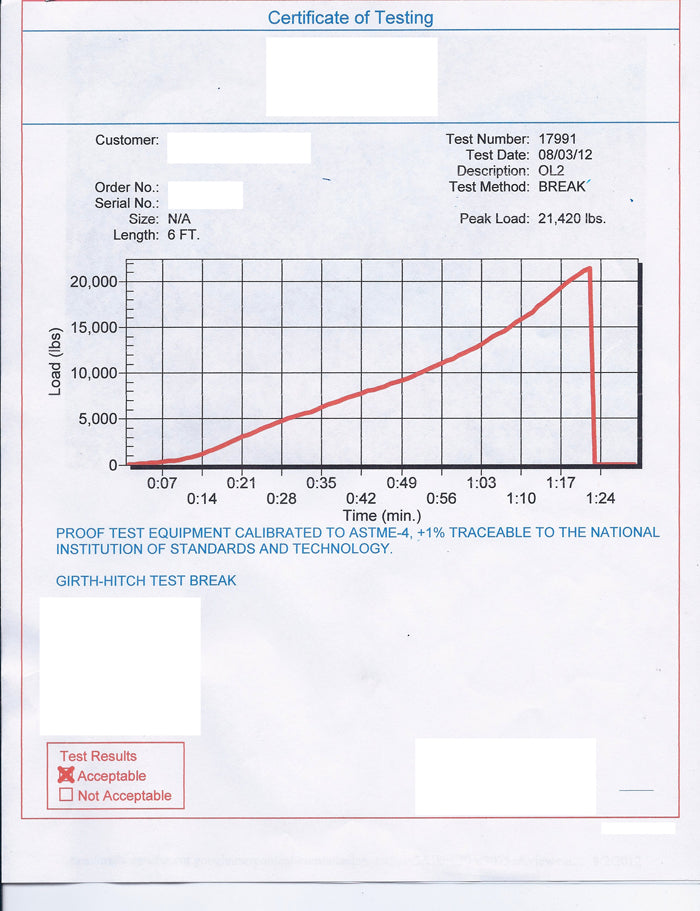

We connected two green spansets together with a girth hitch and then pulled them to destruction.

The force we achieved was 21,420 lbf (95.3 kN). Given that our spansets have a 5:1 safety ratio, the green spansets have a 4,280 lbf working load limit with this configuration.

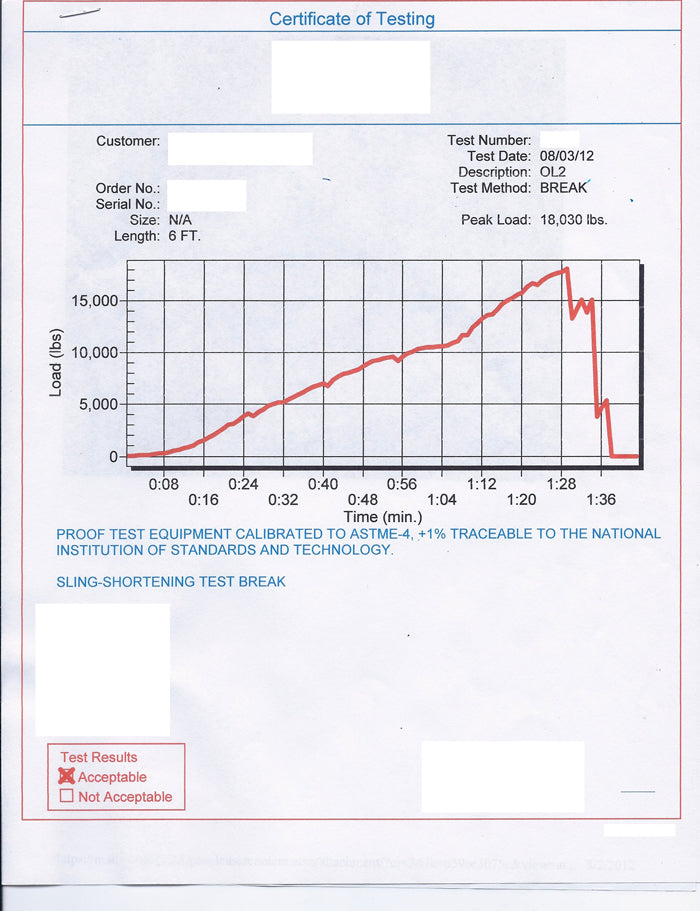

We used the Adjustable Length Spansets technique and pulled the sling to destruction.

The force we achieved was 18,030 lbf (80.2 kN). Given that our spansets have a 5:1 safety ratio, the green spansets have a 3,600 lbf working load limit with this configuration.

The results were quite surprising for the adjustable length spansets technique as well as the girth hitch technique. I thought for sure that the girth hitch would have a lower force than this and vice versa for adjustable length spansets.

Given the max forces we use in slacklining, these numbers are very comforting. Using any of these techniques with any type of slackline, we can be confident we will be well within the working load limit of our slings.

Given the past testing done with spansets by the manufacturer, these results can be extrapolated to all the spanset types. This means that we can apply these results to the purple spansets as well. Here is a nice chart with the breaking strengths and working load limits for both green and purple spansets:

| Method | Purple Spanset | Green Spanset | ||

|---|---|---|---|---|

| WLL | MBS | WLL | MBS | |

| 4-Point Sliding-X | 29.6 kN (6,650 lbf) | 147.9 kN (33,250 lbf) | 59.2 kN (13,300 lbf) | 296.0 kN (66,550 lbf) |

| Girth Hitch | 9.5 kN (2,125 lbf) | 47.3 kN (10,625 lbf) | 19.0 kN (4,250 lbf) | 95.3 kN (21,420 lbf) |

| Adjustable Length Spanset | 8.0 kN (1,800 lbf) | 40.1 kN (9,015 lbf) | 16.0 kN (3,600 lbf) | 80.2 kN (18,030 lbf) |

I'd like to test a few other methods of use with the spansets in the future, maybe 3-point sliding-x and the overhand knot. If you have any other methods that you would like to see broken, please mention them in the comments below. Once again, thanks for reading, I hope this info is helpful to you folks out there!

| Product | Price | Quantity | Options | |||||

|---|---|---|---|---|---|---|---|---|

| Features |

| Availability: |

| Price |

| Options |

| Actions |

← Older Post Newer Post →

0 comments