You have no items in your shopping cart.

0

You have no items in your shopping cart.

Slack Science, powered by Balance Community: Slackline Outfitters, is a blog run by Jerry Miszewski about slacklining. He offers tips and tricks to various parts of setting-up, taking down, in-depth looks at various aspects of a setup, and hints at walking slacklines.

Jerry's long history with the sport of slackline has given him a wealth of knowledge that he loves to share with his fellow slackliners. Slack Science is a place anyone and everyone to come and learn about our wonderful sport of slacklining.

Introduction Today we are going to analyze whether installing webbing into an Alpine WebLock 4, 5, or 6 fully upside-down has any effect on the holding power or strength of...

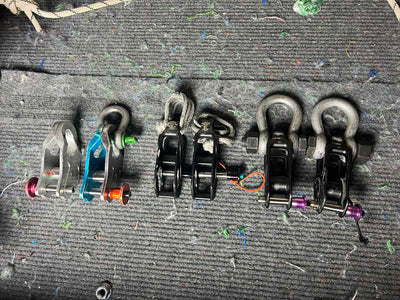

Read more >Introduction Today we are looking at the Alpine WebLock to see which version retains the most strength. We are only looking at the Alpine WebLock 4.0, 5.0, and 6.0 series...

Read more >Introduction Today we are looking at the MightyLock and what sort of strength retention values we get on different types of slackline webbing. Not only are we interested in what...

Read more >Introduction Today we are going to look at an issue that has popped up with our recent Spider Silk MK4 hi-tech slackline webbing. There was an incident where someone was...

Read more >Introduction Today we are going to take a deep dive into the Adjustable Anchor Webbing and it's various usage cases. In 2014, we released this webbing in a different form....

Read more >Slackline webbing, the material that defines our sport. Every time we slackline, we are using some sort of slackline webbing, usually to be walked on. Because of how much we...

Read more >Webbing slippage is a major issue with the current weblock design that has become a standard. In numerous studies performed by a number of individuals, it has been shown that...

Read more >In this article, we will be going over best practices for taping a highline in the most efficient way possible. For longer highlines, taping can be quite the chore. Also,...

Read more >In this article, we will be discussing the spacing of tapes on highlines, good practices for this, and a few tips for optimizing your highline tapes for various types of...

Read more >In this article, we will be looking at a few different methods of taping highlines. Some of these taping styles are what's known as "Slider Tapes", which allow one or...

Read more >In this article we will be discussing a few different styles of tape that are commonly used for taping highlines, their pros and cons, and when/where to use them in...

Read more >In this article, we will be discussing the preparations of the gear and the rigging of GGBY 2017. This year was the first year that this festival was run in...

Read more >| Product | Price | Quantity | Options | |||||

|---|---|---|---|---|---|---|---|---|

| Features |

| Availability: |

| Price |

| Options |

| Actions |